Hadley Group makes corrugated curver investment

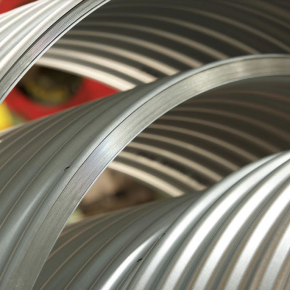

Hadley Group has reaffirmed its commitment to continually improve its UK production capabilities, as it has invested in a new corrugated curver at its Oldbury facility.

The benefits of the new corrugated curver are already proving worthwhile, further bolstering Hadley Group’s production capabilities and its ability to shape metal.

This is helping the company to expand its reach into new markets, particularly within the agriculture sector.

The new corrugated curver takes a sinusoidal metal sheet and bends the material in a gradual way, using a series of rolls housed within the machine.

Unlike some alternatives, Hadley Group’s corrugated curver is not limited to simply producing smile and half-circle units. The new machine is capable of producing a more comprehensive assortment of shapes, such as L-shape units, circles or rounded squares.

With the new and improved corrugated curver in its portfolio, Hadley Group can now manufacture large sheets of metal, incorporating useful architectural curves ideal for grain or hay storage in farms or for liquid storage tanks for multiple industries.

Along with a number of other Hadley Group cold rolled steel profiles, these new products deliver a unique combination of durability, stability and value.

Hadley Group has been operating a similar machine to the corrugated curver for over 30 years, however, this newer version has a range of additional benefits over the older model.

As well as its increased production capability, the new corrugated curver is heavily automated, allowing users to program the required dimensions before operating the machine automatically.

Operators can store, recall and edit up to 50 programs on the machine, which functions through the use of touchscreen technology.

The machine’s automation capabilities mean less manual handling, so it is also a safer process. The operators are responsible for guiding the metal into the curver and monitoring accuracy of performance.

Speaking on the addition of the corrugated curver to Hadley Group’s portfolio, Adam Darby, Plant Manager at Hadley Group’s Oldbury site, commented: “I’ve been working at Hadley Group for many years and during that time one thing that has stood out above anything else is the company’s willingness to reinvest in itself.

“The Oldbury branch alone has seen serious investment in the past two years, in particular. We’ve secured a complete flexible production line, with another due soon.

“Both of these were considerable financial outlays, but will bring significant benefits, particularly in terms of output. Now, we have the new corrugated curver in place as well, we are in an ample position to spearhead further growth.”

Adam continued: “Hadley Group is looking to achieve a £200m turnover result by 2020. It’s a lofty goal, but something we believe we can attain with the right approach.

“As a company we’ve recently acquired like-minded firms such as Hadley Steel Framing and EWS Manufacturing to help us grow. At the same time, we’re also reinvesting into our own processes.

“The investment in the corrugated curver represents this approach and helps bring us closer to our goal.”

The investment has once again underlined Hadley Group’s commitment to continual improvement and its ability to deliver increasingly innovative solutions to complex challenges across industries.

Latest news

19th April 2024

ASSA ABLOY: Access solutions can impact sustainability performance across the full life-cycle of a building

Embedding sustainability within any organisation requires a broad, strategic perspective. Scrutiny should include the physical infrastructure itself: According to the IEA, buildings consume around 30% of global energy*. ASSA ABLOY has more…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Case Studies, Doors, Facility Management & Building Services, Information Technology, Research & Materials Testing, Retrofit & Renovation, Security and Fire Protection, Sustainability & Energy Efficiency, Video of the Week

19th April 2024

British weather doesn't dampen spirit for new HMG Garden Paint

Despite one of the wettest starts to the year on record, customers are starting to plan for brighter days with HydroPro Garden Paint from HMG Paints.

Posted in Articles, Building Industry News, Building Products & Structures, Garden, Innovations & New Products, Paints, Paints, Coatings & Finishes, Restoration & Refurbishment, Retrofit & Renovation, Site Preparation, Sustainability & Energy Efficiency, Waste Management & Recycling

18th April 2024

Abloy UK showcases new digital portfolio at The Security Event 2024

Abloy UK is set to unveil its latest line-up of access control systems at The Security Event 2024, welcoming guests to explore its cutting-edge electromechanical and digital solutions on stand 5/F50.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Doors, Exhibitions and Conferences, Facility Management & Building Services, Health & Safety, Information Technology, Retrofit & Renovation, Security and Fire Protection

18th April 2024

Strand is a Failsafe Choice for Emergency Exit and Panic Hardware

In times of emergency, you’re in safe hands with Strand Hardware. Although there are many considerations for building specification, few decisions can be as critical as selecting the right emergency exit/panic hardware.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

Sign up:

Sign up: