How does powder coating stick to wood?

Many manufacturers are choosing to enhance the aesthetic appeal of their wooden products by powder coating them. However, as wood does not usually respond well to heat, people have asked how powder coating sticks to it.

According to PB Metal Finishing Systems, there are three key elements in effective powder coating: selecting the right type of wood, applying the heat correctly and charging the powder.

A guide to powder coating

Choosing the right wood

As it comprises an engineered board of compressed, assorted adhesives, wood fibres and resins, medium density fibre wood (MDF) has been deemed the most suitable for powder coating by researchers.

It has the right moisture content and bond strength to generate an electric current and make the powder coating stick.

Heat application

To begin the powder coating process, the wood board must conduct an electric current.

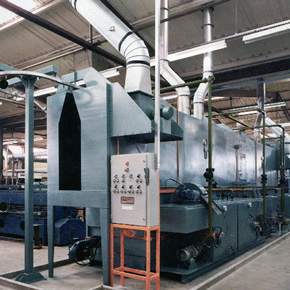

In order to draw the moisture to the surface of the wood, the board is heated to a high temperature, relatively quickly, in an industrial oven. Such appliances are supplied by PB Metal Finishing Systems in a range of sizes and temperatures, varying from 50°C to 500°C.

Once the board has been sprayed, it is heated for a second time to ensure that the powder bonds to the wood.

Charging the powder

After the heated MDF has conducted an electric current, it can be powder coated. Two different power materials are available: UV-cured and thermal cure.

UV-curable powders require minimum heat. Once the coating has been applied to the wood, the parts are inserted into a convection oven, where the coating is left to melt for between two and ten minutes.

The board is then exposed to an ultraviolet light for several seconds to allow the finish to harden. Finally, the parts are left to cool.

For thermal cure powders, ovens which combine infrared and convection heating are required. The powder is melted by the thermal energy that is produced; this allows it to flow into a level film and cure or crosslink into a finished film. Again, minimal heat is required for curing.

Latest news

22nd April 2024

New EJOT role will develop strategic support for UK flat roofing sector

EJOT UK has taken a major step in the expansion of its support for the flat roofing market by appointing one of its most experienced building envelope fastening specialists as its first sector-dedicated business development manager.

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Innovations & New Products, Posts, Recruitment, Restoration & Refurbishment, Retrofit & Renovation, Roofs

22nd April 2024

Access2 Wins ADSA-Sponsored Award at AI Specification Awards

Access2 clinched the ADSA-sponsored Product Design and Innovation Award (Electronic) at the AI Specification Awards 2024 on Thursday.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Awards, Building Associations & Institutes, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Information Technology, Innovations & New Products, Retrofit & Renovation, Security and Fire Protection, Video of the Week

19th April 2024

ASSA ABLOY: Access solutions can impact sustainability performance across the full life-cycle of a building

Embedding sustainability within any organisation requires a broad, strategic perspective. Scrutiny should include the physical infrastructure itself: According to the IEA, buildings consume around 30% of global energy*. ASSA ABLOY has more…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Case Studies, Doors, Facility Management & Building Services, Information Technology, Research & Materials Testing, Retrofit & Renovation, Security and Fire Protection, Sustainability & Energy Efficiency, Video of the Week

19th April 2024

British weather doesn't dampen spirit for new HMG Garden Paint

Despite one of the wettest starts to the year on record, customers are starting to plan for brighter days with HydroPro Garden Paint from HMG Paints.

Posted in Articles, Building Industry News, Building Products & Structures, Garden, Innovations & New Products, Paints, Paints, Coatings & Finishes, Restoration & Refurbishment, Retrofit & Renovation, Site Preparation, Sustainability & Energy Efficiency, Waste Management & Recycling

Sign up:

Sign up: