Viega’s Megapress provides ideal solution for National Gallery leads

Viega’s Megapress connection technology has been specified as the ideal solution for a section of pipe relocation work at The National Gallery in London.

The industry-first press connection system for thick-walled steel tube, Megapress, ensured the installation of steel pipework for the building’s heating and chilled water HVAC systems could take place without disruption to the gallery space, which remained open during the project.

The work was necessary in preparation for a gallery extension, set to take place in January 2019.

Before the building work could take place, it was vital all pipe routes were relocated, bypassing the location of the extension, so the other gallery spaces could continue to remain open throughout the planned building work.

Colin Garbutt, Contracts Manager at Capri Mechanical Services Ltd., selected Viega’s Megapress due to the specific range of needs the gallery space and its displays necessitated.

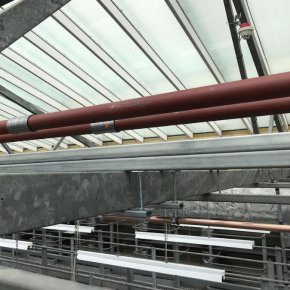

Colin highlighted the difficult circumstances, which involved taking the pipework up a riser and across the top of the gallery through a ventilation and services space.

Colin commented: “For this installation, speed, cleanliness and minimal noise were key requirements to make sure we did not disrupt the gallery space which remained open below us.

“Hot works were not an option in such an environment and it would have been incredibly difficult for us to get the machinery needed for a screw system into such a tight space.

“Megapress allowed us to carry out the work quickly, cleanly and efficiently – which was ideal.”

In total, more than 100 Megapress connections were installed including 2″ connections for the chilled water system and 1¼” to 1½” connections for heating pipes.

Colin added: “I had previously worked with press connection systems, but I had not tried Viega’s steel press connection before.

“To secure the specification it was necessary for us to gain the permission of the gallery management team, so I performed a demonstration with the help of Viega’s technical team.

“The staff were impressed with the system as steel press connections had not been used at the site previously and it fulfilled all the access and safety needs required by the job.”

Viega’s Megapress range includes over 300 different fittings and can be used on pipes up to 4″ in diameter.

The range also includes fittings certified for use on gas installations and all Megapress products feature Viega’s SC-Contur technology, designed to alert the installer to any fittings that may be inadvertently missed.

Latest news

16th April 2024

Mitsubishi Electric set to host CIBSE Journal webinar

Mitsubishi Electric will host a CIBSE Journal webinar on Wednesday 24th April 2024 at 1pm to discuss the legislation and initiatives driving changes in the way we will need to heat, cool and ventilate large commercial buildings to reach net zero emissions in the UK.

Posted in Air Conditioning, Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Information Technology, Pipes & Fittings, Plumbing, Seminars, Sustainability & Energy Efficiency, Training

16th April 2024

Hamworthy: What to consider when choosing a heat pump?

At the heart of an efficient heat pump system lies an important element: the refrigerant – Jason Allen, Commercial Product Manager, Groupe Atlantic UK, ROI & NA. Hamworthy Heating is a Groupe Atlantic brand.

Posted in Articles, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Pipes & Fittings, Plumbing, Retrofit & Renovation, Sustainability & Energy Efficiency

15th April 2024

EJOT Colorfast chosen for Kingspan’s highly sustainable new Asian factory

More than 120,000 EJOT Colorfast self-drilling fasteners have helped Kingspan to create a thermally superior, visually-appealing building envelope for its first purpose-built manufacturing plant in South East Asia.

Posted in Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Posts, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Sustainability & Energy Efficiency

15th April 2024

ASSA ABLOY helps new manufacturing plant achieve LEED Gold certification

Improving sustainability performance is becoming a higher priority for building developers, owners and users. One consequence is fast-growing demand for green building certifications — and therefore specification. Specialist input can make the difference between hitting and missing a project target, as ASSA ABLOY explains here…

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, BIM, Infrastructure & CAD Software, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Case Studies, Doors, Facility Management & Building Services, Information Technology, Retrofit & Renovation, Security and Fire Protection, Sustainability & Energy Efficiency

Sign up:

Sign up: