Ecophon Hygiene™ provides high performance solutions for any application

Ecophon has optimised its Hygiene™ range of acoustic solutions, to make it easier to specify the solution that best meets a project’s specific acoustic and hygiene demands.

Designed to meet differing requirements across a wide range of applications, the range includes options suitable for areas where deep or frequent cleaning is required.

The Ecophon Hygiene™ family comprises the Clinic™, Meditec™, Protec™, Performance™ and Advance™ product groups and is suitable for use both in new builds and refurbishments.

For projects across the healthcare, electronics, food and pharmaceutical industries, the range allows specifiers to select the products that not only meet the required levels of acoustic performance but also the necessary cleanability, durability, particle repellence and bacterial resistance.

Ecophon Hygiene™ includes products that meet all levels of cleanability from a dry vacuum and wet cleaning with a microfibre cloth to advanced techniques that include chemical, pressure, steam and hydrogen peroxide vapour cleaning. This means specifiers can select the most cost-effective option for the requirements of each area – allowing budget allocation to be optimised.

All products within the Ecophon Hygiene™ range have been tested and certified according to ISO 846 for resistance to both fungal and bacterial growth. As with all Ecophon’s products, the Ecophon Hygiene™ range has been engineered to support excellent indoor air quality (IAQ) to further contribute to a healthy indoor environment.

The entire range has been independently tested to confirm it meets the highest standards for emissions including Volatile Organic Compounds (VOC) and formaldehyde. All Ecophon products meet French VOC A or VOC A+ standards – currently the highest level of certification for VOCs.

Alan Crampton, Sales Director at Ecophon explains: “The Ecophon Hygiene™ range makes it simple for specifiers to select the right product both in terms of the acoustics and requirements specific to the application. With our commitment to testing and certification of products on criteria including durability, chemical resistance, bacterial resistance, fire safety and IAQ, customers can also be assured of the products’ performance.”

Latest news

17th May 2024

Vandersanden bricks ensure student accommodation blends with Oxford heritage

An eco-friendly development targeting the Passivhaus Low Energy Building Standard, Castle Hill House provides undergraduate accommodation for students of St Peter’s College, University of Oxford – Vandersanden bricks feature there.

Posted in Articles, Bricks & Blocks, Building Industry News, Building Products & Structures, Case Studies, Facades, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Walls

16th May 2024

ASWS renovates steel window frontage to Edgware Road events venue

Renovating the ageing steel windows within the frontage to a very popular events venue on the Edgware Road posed particular challenges for Associated Steel Window Services (ASWS).

Posted in Articles, Building Associations & Institutes, Building Industry News, Building Products & Structures, Building Services, Building Systems, Case Studies, Glass, Glazing, Lighting, Restoration & Refurbishment, Retrofit & Renovation, Steel and Structural Frames, Windows

16th May 2024

Mitsubishi Electric opens state-of-the-art heat pump training centre in Livingston

Mitsubishi Electric has opened a new training centre at its factory complex in Livingston, Scotland, in answer to the UK’s growing demand for heat pumps.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Information Technology, Innovations & New Products, Pipes & Fittings, Plumbing, Posts, Retrofit & Renovation, Sustainability & Energy Efficiency, Training

15th May 2024

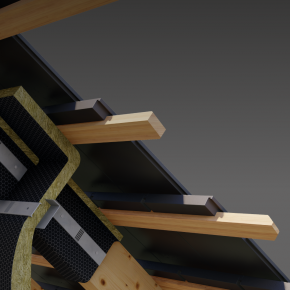

ROCKWOOL® announces launch of new Fire Barrier EN

To help designers and specifiers improve building fire safety, stone wool insulation manufacturer ROCKWOOL® has launched a new fire barrier product that is tested in accordance with the latest BS EN standards.

Posted in Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Systems, Concrete, Cement, Admixtures, Drainage, Guttering, Soffits & Fascias, Health & Safety, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Innovations & New Products, Insulation, Pipes, Pipes & Fittings, Plumbing, Retrofit & Renovation, Timber Buildings and Timber Products, Walls

Sign up:

Sign up: