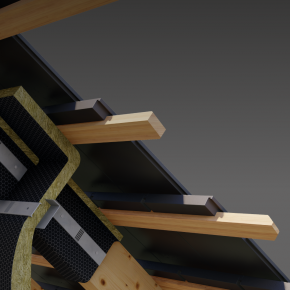

How prefabricated wood elements can ensure faster on-site construction

MetsäWood’s prefabricated wood elements have been proven to lead to faster building turnaround and, in turn, more profitable projects.

Up to 1,500m2 of the brand’s leading Kerto LVL (Laminated Veneer Lumber) roof panels can be assembled within one working day, which has lead to shorter schedules on 70 percent of projects that have used the elements.

Likewise, according to construction professionals interviewed by McGraw-Hill Construction, 65 percent of project that used prefabricated elements had decreased budgets,

This was the case at the headquarters of the Diesel-Benelux Company in Amsterdam, where Kerto LVL roof elements helped keep to a tight building schedule of 9 months.

On-site weather protection

In addition to shorter construction times, using prefabricated elements means weather-related risks are virtually eliminated. Prefabricated wood elements shield the building site beneath, providing protection against all weather types including snow loads and heavy winds.

At the DB Schenker logistics centre inFinland, Kerto LVL roof panels were used to create a roof over the building in just 15 days – the same amount of time used to erect a temporary tent for weather protection.

“Using prefabricated roof panels ensured that the rest of the work could be completed in a protected environment and without additional costs for temporary protection,” commented Matti Kuittinen, architect and researcher from Aalto University.

Minimising accidents

Kerto LVL is manufactured under controlled indoor conditions at MetsäWood’s prefabrication plant, meaning some of the more dangerous on-site construction phases, such as building a roof from beams, panels and bitumen at heights, are no longer required.

Visit Supplier's page

Latest news

17th May 2024

Vandersanden bricks ensure student accommodation blends with Oxford heritage

An eco-friendly development targeting the Passivhaus Low Energy Building Standard, Castle Hill House provides undergraduate accommodation for students of St Peter’s College, University of Oxford – Vandersanden bricks feature there.

Posted in Articles, Bricks & Blocks, Building Industry News, Building Products & Structures, Case Studies, Facades, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency, Walls

16th May 2024

ASWS renovates steel window frontage to Edgware Road events venue

Renovating the ageing steel windows within the frontage to a very popular events venue on the Edgware Road posed particular challenges for Associated Steel Window Services (ASWS).

Posted in Articles, Building Associations & Institutes, Building Industry News, Building Products & Structures, Building Services, Building Systems, Case Studies, Glass, Glazing, Lighting, Restoration & Refurbishment, Retrofit & Renovation, Steel and Structural Frames, Windows

16th May 2024

Mitsubishi Electric opens state-of-the-art heat pump training centre in Livingston

Mitsubishi Electric has opened a new training centre at its factory complex in Livingston, Scotland, in answer to the UK’s growing demand for heat pumps.

Posted in Articles, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Facility Management & Building Services, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Information Technology, Innovations & New Products, Pipes & Fittings, Plumbing, Posts, Retrofit & Renovation, Sustainability & Energy Efficiency, Training

15th May 2024

ROCKWOOL® announces launch of new Fire Barrier EN

To help designers and specifiers improve building fire safety, stone wool insulation manufacturer ROCKWOOL® has launched a new fire barrier product that is tested in accordance with the latest BS EN standards.

Posted in Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Systems, Concrete, Cement, Admixtures, Drainage, Guttering, Soffits & Fascias, Health & Safety, Heating Systems, Controls and Management, Heating, Ventilation and Air Conditioning - HVAC, Innovations & New Products, Insulation, Pipes, Pipes & Fittings, Plumbing, Retrofit & Renovation, Timber Buildings and Timber Products, Walls

Sign up:

Sign up: