NARM: Five reasons to avoid ‘under-spec’ rooflights and specifying tips

NARM, the National Association of Rooflight Manufacturers, has recently received a number of complaints relating to glass rooflights – this article from the Association explores them in more detail.

These rooflights have either been sourced from a disreputable manufacturer, or fabricated by a non-specialist builder.

NARM Product Standards Representative Jeremy Dunn highlights a number of concerns regarding these.

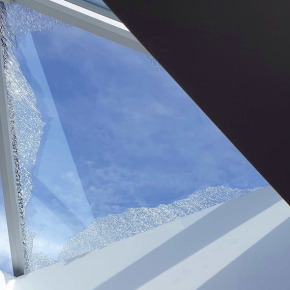

Over recent years, there’s been a huge surge in popularity for modular flat glass rooflights, which are widely specified for domestic and commercial projects – and with good reason.

There’s a large range of excellent, very high quality examples available from reputable suppliers, all of which offer superb aesthetics and very high performance with excellent U-values.

However, NARM has recently received a number of complaints regarding product performance from individuals who have installed or commissioned what they believed to be high quality products, only to be disappointed. More importantly, a number of these instances have also revealed major safety concerns.

As the trade association representing bona fide high quality UK rooflight manufacturers, we’re concerned that this minority of ‘rogue’ manufacturers are giving our industry a bad name and we’d like to set the record straight.

So, here are the reasons why you should reject under-spec rooflights and how you can avoid being ‘sold a dud’.

1. Safety of building occupants

To ensure those below the rooflights are safe, the first choice for the inner pane of a rooflight should be a laminated glass, as this minimises the risk of any glass falling into the room beneath and consequent injury, if the inner pane should break.

Toughened glass inner panes bring a risk of shattering and falling into the room beneath (occasionally spontaneously, but certainly if impacted). NARM is aware of some manufacturers taking advantage of the fact that the term ‘toughened’ implies safety. In this instance, it does not.

British Standards define that inner panes must always be laminated wherever rooflights are more than 5 metres above floor level (increased to 13 metres in limited circumstances) or are located over water (eg swimming pools).

The British Standard may permit use of toughened inner panes in other applications but only if a stringent risk assessment is carried out, confirming that its use does not give any additional risk to those below the rooflight.

It is difficult to see how use of a toughened rather than laminated glass inner pane doesn’t present a risk to anyone beneath the rooflight, so you should always ensure that the inner pane is laminated glass.

Some more economical designs consist of nothing more than a double glazed unit stepped on all four sides with no perimeter frame, with the outer pane sealed to the top of an upstand and the inner pane hanging inside the upstand.

Such designs are not preferred, having much greater reliance on quality of site installation, but if they are used it is essential that the installer provides a continuous support for the inner pane on all four sides, to avoid risk of the whole rooflight dropping into the building beneath if the outer pane should be broken.

Should this be overlooked or the work carried out to a poor standard, there is a serious risk of injury to anybody below should the outer pane of glass break or the edge seal fail.

2. Safety for personnel accessing the roof

In addition to using a laminated inner pane to protect building users, rooflights can also be specified and designed to be non-fragile*.

This is intended to ensure that anyone accidentally walking or falling onto the rooflight will not fall through it, even if the glass is broken or the rooflight damaged.

In this instance, a 9.5mm or 11.5mm laminated inner pane is usually necessary (depending on rooflight size) to comply with non-fragility requirements.

CDM Regulations require that a risk assessment should be carried out for every construction project, and this should define the measures required to prevent significant risk of anyone falling through a rooflight.

Wherever there may be risk of anyone ever being on a roof near a rooflight that they could accidentally step or fall onto (eg for maintenance purposes), you should specify a non-fragile rooflight.

3. Watertightness and water run-off

Another major cause for complaints has been leaking rooflights causing damage to roof structures and interior decorations.

NARM has been contacted regarding instances where the glazing frame has been poorly designed, or the rooflight has been installed poorly and/or without sufficient pitch to allow water run-off, resulting in water building up on the glazing and eventually penetrating edge seals.

Most high quality glass rooflights incorporate a glass unit factory bonded into a fully thermally broken aluminium frame, which includes a drip detail to ensure the unit is fully watertight as soon as it is fitted onto an upstand.

They should be sealed to the upstand on site (for airtightness as well as watertightness), but the seal is only a secondary seal, rather than the primary means of preventing water ingress. In some more economic designs there is no frame, and the glass is simply sealed to the upstand on site.

The absence of any drip detail on a frame means water can easily track back on the underside of the glass, and watertightness of the units becomes entirely dependant on the quality of the site applied seal (often onto an upstand which is not flat and level, after the upstand itself has been weathered), which can cause leaks: this style of rooflight should therefore be avoided.

Glass is not completely rigid and any glass rooflight will bow slightly under the effect of gravity. Flat glass rooflights should therefore always be installed at a slight pitch to avoid ponding (which would otherwise occur if the bow created a negative pitch).

Typically smaller rooflights should be installed at 3 degree pitch, and larger flat glass rooflights should be installed at 5 degree pitch.

You should always make sure that the contractor who is building the upstand is aware of this pitch requirement, to avoid the unsightly problems associated with ponding (including rapid dirt build-up, and potentially water ingress).

Some rooflights are offered with “self-cleaning” glass, which is misleading: true self-cleaning glass (such as Pilkington Activ) works best at pitches above 30 degrees, with a minimum pitch of 10 degrees so is not suitable for flat glass rooflights.

Some grades of low maintenance or easy-clean glass can be used, but still require regular cleaning.

4. Security

For domestic properties, Part Q Building Regulations state that rooflights deemed as easily accessible need to be proven to resist criminal attack or incorporate features that are proven to reduce crime.

We’re aware of rooflights being supplied for domestic use with no mention of Part Q. Even rooflights supplied with a laminated inner pane may not pass Part Q testing as the outer could be broken and then the inner pane just lifted out of the hole.

5. Thermal performance

It’s important that manufacturers state ‘whole product’ U-values to ensure thermal performance which will allow compliance with Part L Building Regulations.

Some manufacturers are quoting ‘centre pane’ U-values which do not take into account edge spacers and frame construction. The thermal performance of a rooflight must be considered for the whole assembly, because while glazing may be compliant, poor frame design can affect thermal performance. This can result in higher energy bills for building users and subsequent unwanted higher CO2 emissions.

Remember: a great-looking rooflight isn’t necessarily a great rooflight

NARM has noted that in many cases where complaints have occurred, the manufacturer is targeting homeowners with sophisticated websites and literature focusing heavily on the aesthetics of the product and often claiming excellence in quality standards. Some have even referenced NARM documents on their marketing materials. Beware!

In a crowded marketplace, where some manufacturers are making confusing or untrue claims, careful consideration needs to be given to rooflight choice, if problems of water ingress, ponding or worse still, inadequate safety, are to be avoided.

The good news is that there are many excellent, trustworthy UK suppliers of properly designed rooflights which will offer years of safe and reliable service. One simple and certain way to ensure you’re dealing with such a company, is to establish whether your supplier is a NARM member company.

NARM has stringent membership criteria, a key part of which is that any product supplied by a member company is fully compliant with Building Regulations and meets all required specification and safety standards.

Further information and NARM Technical Documents on safety in relation to rooflight specification, plus a complete list of NARM member companies can be accessed free of charge on NARM’s website, at https://www.narm.org.uk/downloads/safety-on-roofs/

For further information, please contact NARM using the contact details on our website, where you will be directed to the appropriate person.

Click here to visit The Rooflight Association's website

Visit Supplier's page

Latest news

26th April 2024

Alumasc Skyline and Rainwater package specified at Weston-super-Mare Hospital

A package of products from Alumasc Water Management Solutions (AWMS) has been used for the external refurbishment of the roofline at Weston General Hospital in Weston-Super-Mare.

Posted in Aluminium Products, Articles, Building Industry News, Building Products & Structures, Building Services, Building Systems, Case Studies, Cladding, Drainage Services, Drainage, Guttering, Soffits & Fascias, Fascias, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Walls

26th April 2024

Hush Acoustics optimises fleet operations by securing FORS Gold accreditation

Hush Acoustics has invested in the safety and sustainability of its commercial vehicle fleet by achieving Gold status in the Fleet Operator Recognition Scheme (FORS).

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Ceilings, Facility Management & Building Services, Floors, Health & Safety, Insulation, Restoration & Refurbishment, Retrofit & Renovation, Site Preparation, Sustainability & Energy Efficiency, Walls, Waste Management & Recycling

26th April 2024

Safeguard Europe: Penetrating damp - how to diagnose the damage

As Safeguard gets ready to deliver another informative session of one of its most popular webinars, the company outlines some of the most common reasons for rain penetration through brickwork.

Posted in Articles, Bricks & Blocks, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Damp & Waterproofing, Facility Management & Building Services, Information Technology, Posts, Render, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training, Walls

25th April 2024

ADSA: Competence Initiative Makes Progress

The Joint Competency Initiative (JCI), in which the Automatic Door Suppliers Association (ADSA) is involved, is finalising its first framework for installers within the door, gates and shutter industry.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Associations & Institutes, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Continuing Professional Development (CPD's), Doors, Facility Management & Building Services, Health & Safety, Innovations & New Products, Publications, Research & Materials Testing, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection, Site Preparation

Sign up:

Sign up: