HOPPE: Fire door FAQs – A guide to fire and escape door hardware

HOPPE (UK) shares some of the questions that its technical teams are asked about fire doors and offers advice for specifying compliant door hardware in public buildings…

Can you turn any door into a fire door?

No, a fire door is designed to withstand fire for a set period of time, and it must have fire test evidence to prove this performance. This will usually be a certificate of performance, showing that the door can withstand fire for a certain length of time.

Fire doors have a minimum fire rating of 30 minutes (FD30), but some steel fire doors can achieve 240 minutes of fire resistance (FD240).

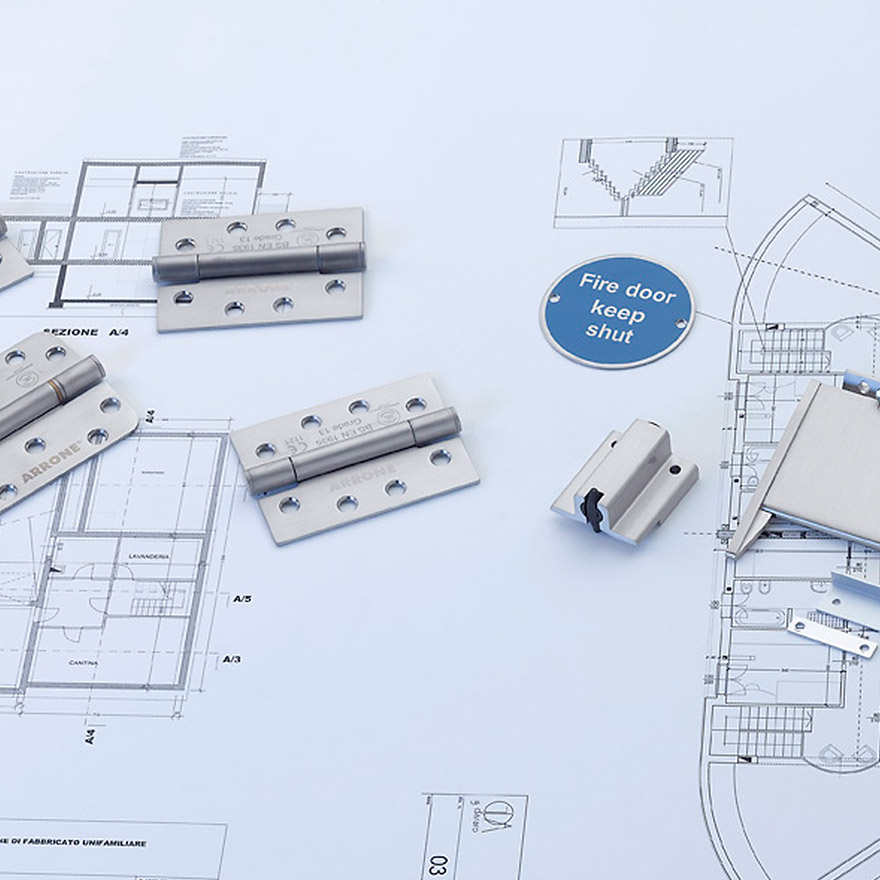

What hardware do I need?

There are three pieces of operational hardware that are critical to a fire door’s performance: hinges, door closing devices and locks. In a fire, these products help to close and secure the doors in the frame for a period of time to allow intumescent protection in the frame to expand and fill the gaps around the door.

To conform to EN1154, the smallest door closer that can be used on a fire door is a size 3. The heavier the door, the more powerful the closer must be. The smallest size 3 is up to 60kg and 950mm wide and the largest size 6 up to 120kg and 1400mm wide.

What is panic and emergency exit hardware and do I need it?

Depending on where the door is located, you may need panic or emergency exit hardware. The type of hardware required will depend on the building’s type, application, its occupation levels, and where the door is in the building. For fire doors on an escape route, panic or emergency exit hardware is mandatory.

Emergency exit hardware is mainly used in buildings where users are familiar with exit routes, such as offices, and are not accessible to the public. Devices for these doors could be a simple push pad type device or a lever handle operating a mortice escape lock or nightlatch.

Panic hardware is used when the general public has access to the building and may not be familiar with the exit routes, for example in hospitals and community buildings. This applies to any room with a capacity of over 60.

Any doors in areas that are accessible to the public must have a device fitted that is operable by a horizontal bar that covers at least 60% of the overall door width. As well as being easier to see and use, it also adds another layer of safety functionality in the event of an emergency

What signs do I need for my fire door?

There are three types of signs for use on fire doors:

– Fire Door Keep Shut – for self-closing doors used for passage of people

– Fire Door Keep Locked – for doors which are locked shut and only used occasionally

– Automatic Fire Door Keep Clear – for doors which are held open using a legal device or are swing-free but revert to self-closing when a fire alarm is activated

I’m about to refurbish my building, what do I need to consider?

If replacing any fire door hardware, the new components must be equal to or better than the fire/mechanical performance of the door.

To tell if a product is ‘like for like’, look at the tested elements and the certification for the products. Check what type of door the ironmongery is tested for use on. A product that has been fire tested for use on an FD30 is not necessarily suitable for use on an FD60 and vice versa (without prior testing on that type of door).

Remedial work should not include any removal of intumescent materials from the door unless damaged. Any replacement of hardware intumescent kits should be the exact same material, size and thickness.

Any works should be carried out by a competent person and should be signed and countersigned by the tradesperson completing the installation and the fire door inspector. All materials used should be clearly listed and a certification file compiled for future reference.

How often should I check and maintain fire door hardware?

A fire door needs regular maintenance and checks to prevent and address issues that could impact performance. There is not a specific frequency stated within law, but HOPPE (UK) recommends at least once per year.

When inspecting the ironmongery on a fire door, here are some key things to check:

– CE marked hinges are firmly fixed with no missing screws

– Seals are fitted at the top and sides of the door

– The door closer shuts the door firmly into the latch from any position

If in doubt about any fire door hardware, consult with the original door manufacturer or contact one of HOPPE (UK)’s Guild of Architectural Ironmongers (GAI) qualified experts for advice on 01902 484 400.

Latest news

26th July 2024

Enfield Speciality Doors completes world-class project for Atlas Copco HQ

A rundown office and warehouse building completely transformed into a modern headquarters for Atlas Copco has been fitted with more than 120 internal fire doors from Enfield Speciality Doors.

Posted in Access Control & Door Entry Systems, Articles, Building Industry News, Building Products & Structures, Building Systems, Case Studies, Doors, Interior Design & Construction, Interiors, Posts, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection, Sustainability & Energy Efficiency, Timber Buildings and Timber Products, Wooden products

26th July 2024

Abloy UK launches new white paper

Abloy UK, a leading provider of security and access control solutions, has launched a new white paper.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Information Technology, Innovations & New Products, Publications, Research & Materials Testing, Security and Fire Protection

26th July 2024

MCRMA Member Profile: David Roy, Director of Roofconsult

David Roy of MCRMA member company Roofconsult has more than 50 years’ experience to draw upon working in the building envelope sector and a unique perspective on how it has changed in that time.

Posted in Articles, BIM, Infrastructure & CAD Software, Building Associations & Institutes, Building Industry News, Building Products & Structures, Building Services, Building Systems, Cladding, Information Technology, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Walls

26th July 2024

Strand: Enhancing Door Functionality and Safety

Craig Fox, Sales Director for Strand Hardware, outlines how door industry professionals might apply door limiting stays…

Posted in Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Services, Doors, Facility Management & Building Services, Health & Safety, Restoration & Refurbishment, Retrofit & Renovation

Sign up:

Sign up: