How does powder coating stick to wood?

Many manufacturers are choosing to enhance the aesthetic appeal of their wooden products by powder coating them. However, as wood does not usually respond well to heat, people have asked how powder coating sticks to it.

According to PB Metal Finishing Systems, there are three key elements in effective powder coating: selecting the right type of wood, applying the heat correctly and charging the powder.

A guide to powder coating

Choosing the right wood

As it comprises an engineered board of compressed, assorted adhesives, wood fibres and resins, medium density fibre wood (MDF) has been deemed the most suitable for powder coating by researchers.

It has the right moisture content and bond strength to generate an electric current and make the powder coating stick.

Heat application

To begin the powder coating process, the wood board must conduct an electric current.

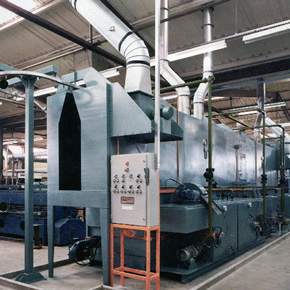

In order to draw the moisture to the surface of the wood, the board is heated to a high temperature, relatively quickly, in an industrial oven. Such appliances are supplied by PB Metal Finishing Systems in a range of sizes and temperatures, varying from 50°C to 500°C.

Once the board has been sprayed, it is heated for a second time to ensure that the powder bonds to the wood.

Charging the powder

After the heated MDF has conducted an electric current, it can be powder coated. Two different power materials are available: UV-cured and thermal cure.

UV-curable powders require minimum heat. Once the coating has been applied to the wood, the parts are inserted into a convection oven, where the coating is left to melt for between two and ten minutes.

The board is then exposed to an ultraviolet light for several seconds to allow the finish to harden. Finally, the parts are left to cool.

For thermal cure powders, ovens which combine infrared and convection heating are required. The powder is melted by the thermal energy that is produced; this allows it to flow into a level film and cure or crosslink into a finished film. Again, minimal heat is required for curing.

Latest news

26th April 2024

Alumasc Skyline and Rainwater package specified at Weston-super-Mare Hospital

A package of products from Alumasc Water Management Solutions (AWMS) has been used for the external refurbishment of the roofline at Weston General Hospital in Weston-Super-Mare.

Posted in Aluminium Products, Articles, Building Industry News, Building Products & Structures, Building Services, Building Systems, Case Studies, Cladding, Drainage Services, Drainage, Guttering, Soffits & Fascias, Fascias, Restoration & Refurbishment, Retrofit & Renovation, Roofs, Walls

26th April 2024

Hush Acoustics optimises fleet operations by securing FORS Gold accreditation

Hush Acoustics has invested in the safety and sustainability of its commercial vehicle fleet by achieving Gold status in the Fleet Operator Recognition Scheme (FORS).

Posted in Acoustics, Noise & Vibration Control, Articles, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Ceilings, Facility Management & Building Services, Floors, Health & Safety, Insulation, Restoration & Refurbishment, Retrofit & Renovation, Site Preparation, Sustainability & Energy Efficiency, Walls, Waste Management & Recycling

26th April 2024

Safeguard Europe: Penetrating damp - how to diagnose the damage

As Safeguard gets ready to deliver another informative session of one of its most popular webinars, the company outlines some of the most common reasons for rain penetration through brickwork.

Posted in Articles, Bricks & Blocks, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Damp & Waterproofing, Facility Management & Building Services, Information Technology, Posts, Render, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training, Walls

25th April 2024

ADSA: Competence Initiative Makes Progress

The Joint Competency Initiative (JCI), in which the Automatic Door Suppliers Association (ADSA) is involved, is finalising its first framework for installers within the door, gates and shutter industry.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Associations & Institutes, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Continuing Professional Development (CPD's), Doors, Facility Management & Building Services, Health & Safety, Innovations & New Products, Publications, Research & Materials Testing, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection, Site Preparation

Sign up:

Sign up: