Selectaglaze Secondary glazing: The retrofit solution to building sustainability

With a UK-wide commitment to net zero by 2050, and approximately 5.4million traditional buildings in England alone, there is a lot of work needed to upgrade both the building fabric and its fittings. Replacing existing windows is not always desirable nor permissible, so secondary glazing can be a very sustainable product choice. Selectaglaze has more…

Retaining embodied carbon

There is no need to remove existing windows, meaning the embodied carbon is retained and there is no waste going to recycling or landfill. This is subject to frames being in good order or repairable but many period buildings have sound windows.

Easily reversible

Most Listed buildings cannot replace their existing single glazed windows so, subject to listed building consents, secondary glazing offers an excellent solution as Heritage bodies accept it as a reversible adaptation.

Long-lasting

Single glass does not degrade or fail, and treated aluminium doesn’t corrode. So the life expectancy of properly maintained secondary glazing can be substantial. Protected from the main elements and not limited by potential failure of sealed units, the life expectancy of secondary glazing could easily exceed that of modern replacement windows.

Thermally efficient

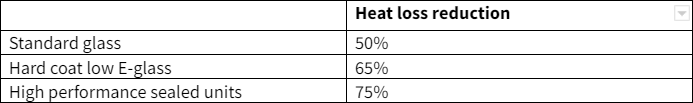

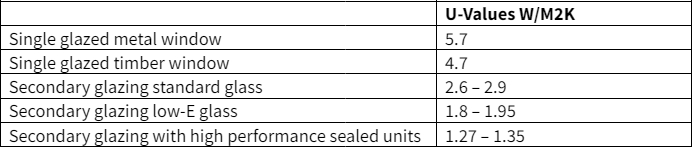

An independent, correctly installed and sealed secondary window frame will minimise air leakage. It also ‘traps’ an insulating layer of air that can reduce heat loss by 50-75%, depending on the glass specification, with increased U-Values and improved EPC and BREEAM ratings.

In single glazed properties

Around 6% of traditional homes are single glazed, many with windows having architectural features that are desirable and need to be retained. Secondary glazing provides an efficient and sympathetic upgrade whilst maintaining the valuable original designs.

In double glazed properties

An estimated 75% of homes have double glazed windows many of which have been installed since the 1980’s. Early designs for sealed units are much less thermally efficient than those needed to meet current standards and latest sustainability targets. Secondary glazing can provide a simple upgrade to these poorly performing systems.

Expert’s view

According to Dr Robyn Pender, Senior Building Conservation Adviser at Historic England ‘despite what is commonly thought, secondary glazing is a much more efficient system than double glazing.

Double glazing places the two panes of glass close together into a single window frame and stops heat transferring through the narrow gap between the panes either by evacuating the air from the space and creating a vacuum or replacing the air with a low-heat-transfer gas.

The combination of vacuums and energy-expensive gases, short lifespans and problems with reuse and recycling mean that ‘insulated glazing units’ (double and triple glazing) can often fail to deliver true energy or carbon benefits: factoring in the lifecycle costs means they come with a very serious risk of maladaptation (costing more energy and/or carbon than they save).

Early glass was even more energy-intensive than modern glass, but even so a PVC double-glazed window will have cost more energy in one replacement cycle (20 years) than the original window in 200 years.’

Case studies

A Grade II Listed Georgian Town House in London has been transformed into an energy efficient home approaching enerPhit standards. The addition of precision fitted Selectaglaze Series 25 vertical sliding secondary glazed unit, with high performance vacuum glass, provided U-values of 1, helping create air tightness close to one air change per hour.

Wiltshire County Hall received a BREEAM Excellent Rating, with a 40% energy reduction due to its remodelling and refurbishment programme across its 1930’s civic building and 1970s office extension. Selectaglaze secondary glazing was installed to over 270 windows to improve the heat retention of the primary windows.

Sustainable supplier

Selectaglaze not only provides products to improve the performance of other buildings but is fully committed to reducing its own carbon footprint, with the drive towards net zero recognised through Planet Mark Certification. Selectaglaze products are made in the UK and have long life expectancy. 30% of aluminium and 35% of glass come from recycled materials and timber is FSC certified.

Selectaglaze’s recent video features behind the scenes of the manufacturing process.

Contact:

Selectaglaze,

Alban Park,

Hatfield Road,

St. Albans,

Hertfordshire,

AL4 0JJ

Phone: 01727 837271

Fax: 01727 844053

Visit Supplier's page

Latest news

26th April 2024

Safeguard Europe: Penetrating damp - how to diagnose the damage

As Safeguard gets ready to deliver another informative session of one of its most popular webinars, the company outlines some of the most common reasons for rain penetration through brickwork.

Posted in Articles, Bricks & Blocks, Building Industry Events, Building Industry News, Building Products & Structures, Building Services, Continuing Professional Development (CPD's), Damp & Waterproofing, Facility Management & Building Services, Information Technology, Posts, Render, Restoration & Refurbishment, Retrofit & Renovation, Seminars, Training, Walls

25th April 2024

ADSA: Competence Initiative Makes Progress

The Joint Competency Initiative (JCI), in which the Automatic Door Suppliers Association (ADSA) is involved, is finalising its first framework for installers within the door, gates and shutter industry.

Posted in Access Control & Door Entry Systems, Architectural Ironmongery, Articles, Building Associations & Institutes, Building Industry Events, Building Industry News, Building Products & Structures, Building Regulations & Accreditations, Building Services, Continuing Professional Development (CPD's), Doors, Facility Management & Building Services, Health & Safety, Innovations & New Products, Publications, Research & Materials Testing, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection, Site Preparation

25th April 2024

BMBI: Value sales in first two months were -3.4% down

The latest Builders Merchant Building Index (BMBI) report shows builders’ merchants’ value sales were down -4.7% in February compared to the same month a year ago.

Posted in Articles, Bathrooms & Toilets, Bathrooms, Bedrooms & Washrooms, Bricks & Blocks, Building Associations & Institutes, Building Industry News, Building Products & Structures, Building Services, Civil Engineering, Concrete, Cement, Admixtures, Drainage, Floors, Hard Landscaping & Walkways, Interior Design & Construction, Interiors, Landscaping, news, Paints, Paints, Coatings & Finishes, Plant, Equipment and Hire, Plumbing, Posts, Publications, Research & Materials Testing, Restoration & Refurbishment, Retrofit & Renovation, Sustainability & Energy Efficiency

24th April 2024

The lowdown on Origin’s New Soho Offering

Origin’s Soho External Door is the first launch in its new generation of products, setting a higher standard for the fenestration industry.

Posted in Access Control & Door Entry Systems, Aluminium Products, Architectural Ironmongery, Articles, Building Industry News, Building Products & Structures, Building Systems, Doors, Innovations & New Products, Posts, Restoration & Refurbishment, Retrofit & Renovation, Security and Fire Protection

Sign up:

Sign up: